The Industrial Development of Electroplating

The Beginning

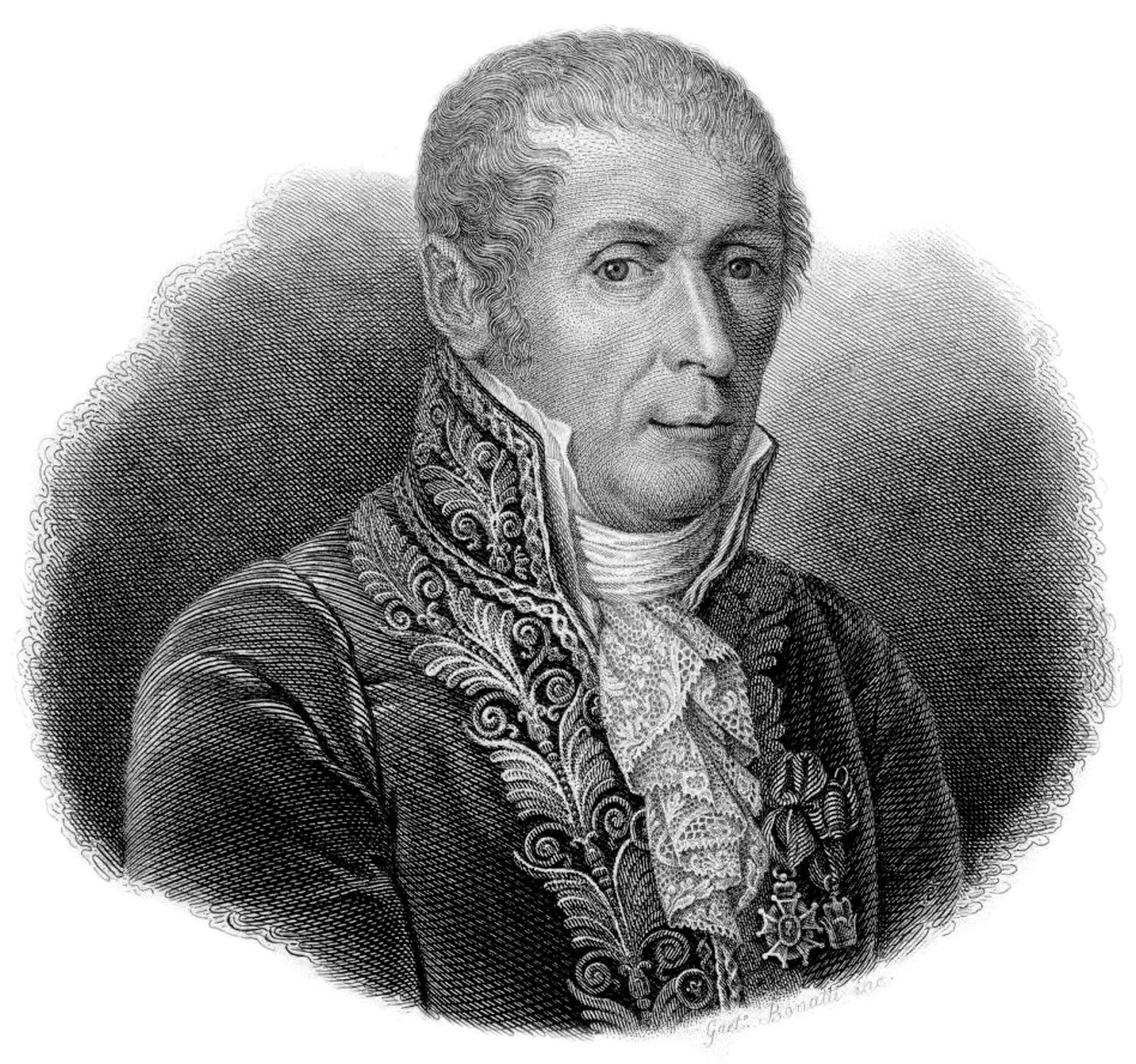

The process of electroplating originated in 1805 and was invented by an Italian chemist named Luigi Brugnatelli.

Like every other inventions, electroplating was built off many other key inventions before it. For example, the voltaic pile, a row of voltaic cells that create an electric current, invented by Alessandro Volta in 1800 boosted its invention later on.

It is believed that Luigi Brugnatelli relied on Volta’s invention as the main source of electricity when inventing electroplating. After many attempts his invention finally evolved, but wasn’t taken so seriously because of Napoleon Bonaparte and the French Academy of Sciences. It is only later in 1839 that the work was taken seriously in Russia and Britain because a similar concept rose. The process was used to electroplate copper printing plates.

In Britain around the same time, a chemist named John Wright discovered that potassium cyanide can be used as an electrolyte solution during the electroplating process. His success took the interest of British cousins George and Henry Elkington, who bought his patent and spread commercial success of plating silverware and manufacture decorative metal.

Electroplating in the 19th Century

The development of electric generators boosted electroplating. With the higher currents available, metal machine components, hardware, and automotive parts requiring corrosion protection and enhanced wear properties, along with better appearance, electroplating shot up!

In addition to that, when the two World Wars took place, aviation industry grew and further developed electroplating industry because of rising need for plating for aviation and military parts.

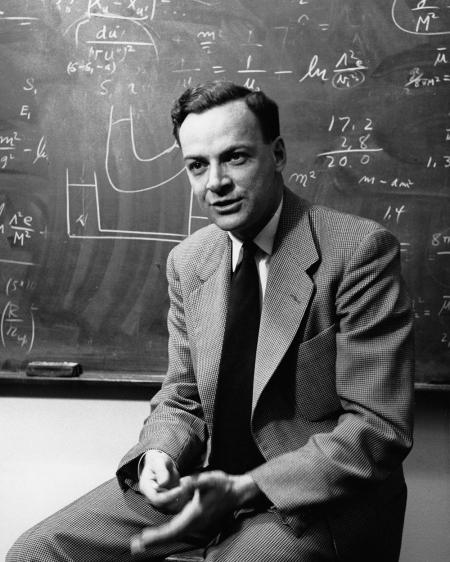

Another electroplating advancement made in the 19th century was when an American physicist, Richard Feynman, developed technology for electroplating metal onto plastic.

Electroplating in the 20th Century and Contemporary Trends

The process of electroplating relatively remained unchanged until the 1940’s. The sudden change came when the rise in electronics industry lead to the replacement of traditional cyanide solutions with safer acid baths on a commercial level. A few decades later, water disposal regulations enforced in the 1970’s streamlined electroplating making it a faster and more efficient process.

At present time, new chemical advancements allow electroplating for a wide range of materials, including but not limited to platinum and osmium. Our electronics industry continues to rely on electroplating for products such as connectors and circuit boards.

Environmentally, waste-water recycling and attempts to minimize work-place chemical exposure are helping ensure that electroplating continues to be safe regardless of chemical changes, and ongoing developments and advancements.